The co-molding of plastic materials allows the creation of finished products made of different types of material. A process that guarantees the highest quality and an excellent aesthetic result.

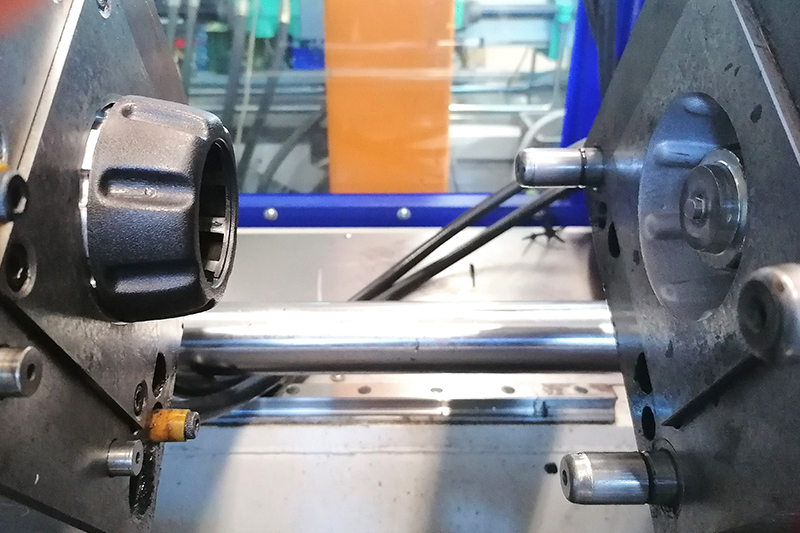

The efficiency of our latest generation presses allows us to print metal-plastic together, in order to insert metal elements in plastic bodies, as in the case of valves, knobs or electronic gears in general.

The result is fast processing, which reduces production costs and optimizes production times, in order to always respect the needs expressed by customers.

Plastic injection on metals or other “inserts” gives rise to a hybrid component of metal and plastic. Our molding technology allows you to create highly complex and integrated hybrid parts. In this way, attention is directed to the inserts under tension or purely mechanical inserts, such as threaded bushings.