TECNOSTAMP, due to its production and sector diversification, uses a very wide range of thermoplastic polymers.

The selection of polymers constitutes a crucial phase in the development of the project and in achieving the result. TECNOSTAMP carries it out with technical-scientific criteria, thanks to its in-depth know-how and partnership with its suppliers.

The polymers are selected with the application of the most suitable formulation for the desired purpose, from the polymer matrix to specific reinforcements, fillers and functional additives (including spheres, short and long glass fibers, mineral fillers, molybdenum disulfide, Kevlar, silicone, PTFE, carbon fibers, stainless steel fibers, graphite, magnets, phosphorus, antistatic, anti-UV, anti-bacterial, self-extinguishing).

Based on specific technical requirements, we are able to address a wide range of preliminary project requirements:

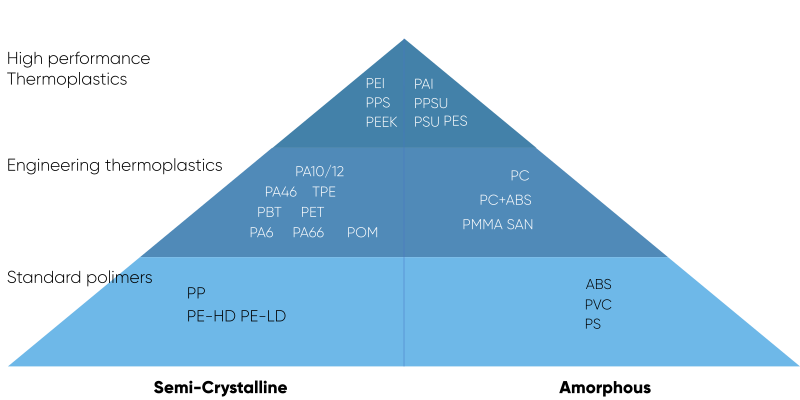

WE ARE ABLE TO WORK WITH A LARGE VARIETY OF POLYMERS, FOCUSING ON THE MOST SOPHISTICATED.

TECNOSTAMP has the know-how, machinery and equipment suitable for processing a wide range of plastics, which include basic polymers, technopolymers and superpolymers.