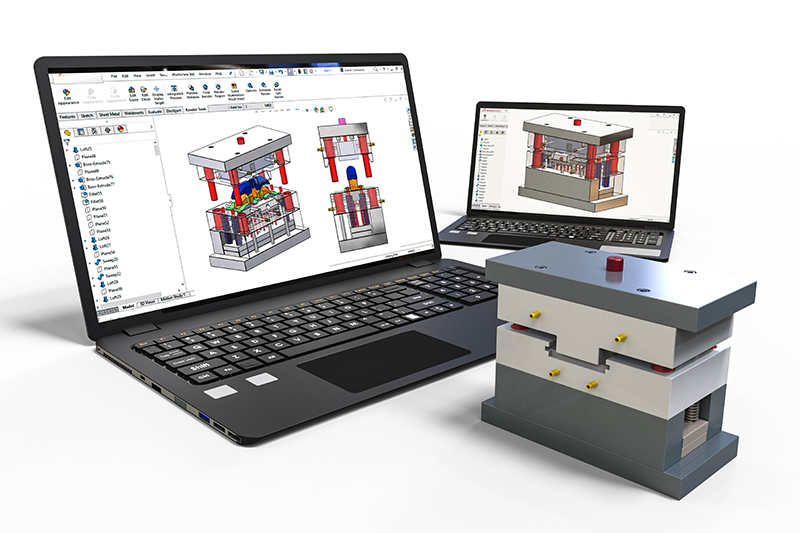

TECNOSTAMP takes care of the management of all new product development activities or the continuous improvement of the performance of existing products, in direct collaboration with the customer.

One of the most important aspects of our work is being able to identify the customer’s needs in the best possible way, in order to propose the most appropriate solution.

TECNOSTAMP appropriately carries out the following activities:

Furthermore, among the accessory services to the design we can provide: