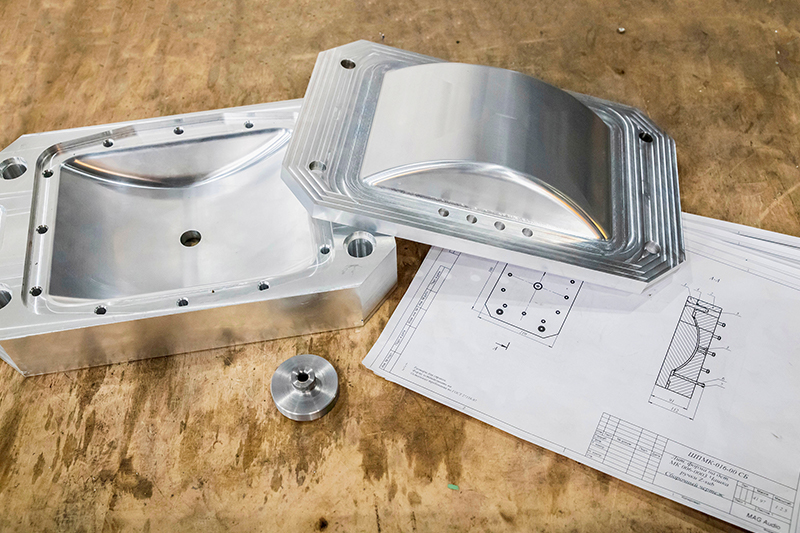

It is an outdated belief that plastic injection molding is only profitable for large series in the automotive field. Thanks to the use of high-strength aluminum molds used in aeronautics, it is possible to produce injection molded parts even for small quantities.

There are two situations that make the production of “quick molds” efficient with easy-to-process materials, such as aluminum:

- The need to obtain functional prototypes to verify their reliability and actual performance, as rapid tooling allows printing with a wide range of polymers.

- The production of small batches.

For the small series necessary, in Tecnostamp the production of the molds begins after a few weeks, and not after months, with an economic advantage compared to the use of a steel series mold or 3D printing.

For very small quantities, in the case of prototype molds we also work with moving parts to remove undercuts.